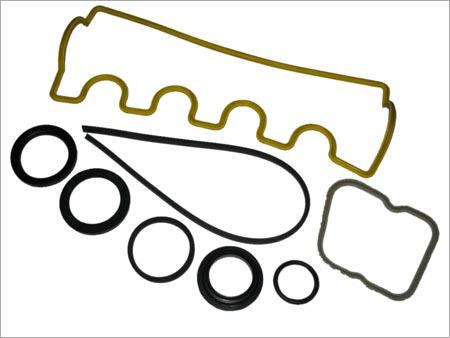

Rubber Gaskets

Rubber Gaskets Specification

- Water Absorption

- Low

- Surface Finish

- Smooth or textured as required

- Usage & Applications

- Sealing, insulation and vibration absorption in pipelines, flanges, pumps, automotive, and industrial machinery

- Diameter

- 10 mm to 1600 mm or as required

- Thickness

- 1 mm to 25 mm

- Compression Ratio

- 50%

- Weight

- Varies with size and thickness

- Volatile Matter (%)

- 1.5%

- Product Type

- Rubber Gasket

- Nitrogen Content (%)

- 1%

- Length

- Custom length as required

- Style

- Flat, ring, or custom cut

- Size

- As per customer requirement or standard sizes

- Part Type

- Industrial sealing component

- Ash %

- 2%

- Tolerance

- 0.2 mm

- Resistance level

- High resistance to oil, chemicals, weathering, ozone, and abrasion

- Color

- Black or as per requirement

- Width

- Customizable, standard range: 5 mm to 1200 mm

Rubber Gaskets Trade Information

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Domestic Market

- All India

About Rubber Gaskets

By having enormous market experience, we are capable of manufacturing, exporting and supplying our precious clients a broad range of Rubber Gaskets. These gaskets are used in various industries and vehicles for preventing the leakage. The offered gaskets are manufactured by our highly knowledgeable professionals using admirable quality rubber and advanced technology as per the latest market requirement. Moreover, these Rubber Gaskets are available for our international clients at market leading prices.

Features:

-

Abrasion resistance

-

Accurate dimension

-

Optimum durability

-

Fine finish

Optimal Sealing Solutions for Industrial Needs

Rubber gaskets are essential for maintaining airtight and watertight seals in critical applications across industries. Their customizable dimensions and styles allow seamless integration with pipelines, machinery, and automotive systems to prevent leaks and ensure stable operation.

Superior Material Properties for Longevity

Our rubber gaskets exhibit high resistance to oil, chemicals, ozone, and abrasion, extending product life and reducing maintenance frequency. The low ash, nitrogen, and volatile matter content ensure purity and reliability, while the compression ratio facilitates efficient sealing under pressure.

Custom Manufacturing Services

Manufactured by leading suppliers, dealers, and exporters in India, these gaskets can be produced to meet specific customer needs, from size and color to surface finish and diameter. With flexible production capabilities, the gaskets fit unique industrial settings and stringent technical requirements.

FAQs of Rubber Gaskets:

Q: How does a rubber gasket enhance sealing and insulation in industrial applications?

A: Rubber gaskets provide a robust barrier between joining surfaces, preventing leaks of fluids or gases and improving insulation. Their high compression ratio allows them to conform to irregular surfaces, ensuring reliable sealing and dampening vibration in pumps, pipelines, and machinery.Q: What types of rubber gaskets are available, and how do I select the right style for my application?

A: You can choose from flat, ring, or custom-cut gaskets based on your systems design requirements. Select the style that matches your flange, pipe, or machinery configuration for optimal sealing and performance.Q: When should I replace a rubber gasket in my equipment?

A: Rubber gaskets should be inspected regularly for signs of wear, cracking, or deformation. Replacement is recommended when you notice leaks, reduced sealing efficiency, or physical damage during routine maintenance.Q: Where can I source customized rubber gaskets for my specific industrial need?

A: Customized rubber gaskets are available from manufacturers, suppliers, exporters, and dealers across India. They can produce gaskets as per your dimensional, color, and surface finish requirements for various application sectors.Q: What is the process involved in manufacturing rubber gaskets with customized specifications?

A: Manufacturers use precise cutting, molding, and finishing techniques to produce gaskets that meet custom thickness, width, diameter, and style requests. Quality checks ensure low ash, nitrogen, and volatile matter levels as well as high resistance to oil and chemicals.Q: How do rubber gaskets contribute to operational safety and efficiency?

A: By providing secure seals and vibration absorption, rubber gaskets minimize fluid leaks, prevent contamination, and reduce mechanical wear. This leads to safer operation, decreased maintenance costs, and extended equipment life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Profiles Category

Thermoplastic Profiles

Diameter : 3 mm 50 mm

Water Absorption : <0.1%

Product Type : Thermoplastic Profiles

Size : Customizable as per requirement

Color : Black, White, Grey, Custom colors available

Resistance level : High chemical and corrosion resistance

Endless Rubber Gaskets

Diameter : 50 mm to 1200 mm

Water Absorption : <1%

Product Type : Endless Rubber Gasket

Size : Custom sizes available

Color : Black

Resistance level : High resistance to abrasion, oil, and chemicals

Silicon Profiles

Diameter : 4 mm to 50 mm (for round profiles)

Water Absorption : <0.5%

Product Type : Silicon Profiles

Size : Standard and custom sizes available

Color : Red, White, Transparent, and other custom colors

Resistance level : High resistance to temperature, moisture, acids, alkalis, weathering, and UV

Pipe Clamps Rubber

Diameter : Compatible with pipe diameters from 1/2 to 8

Water Absorption : Low

Product Type : Rubber Lined Pipe Clamp

Size : Available in multiple sizes to fit various pipe diameters

Color : Black (Rubber); Silver (Clamp)

Resistance level : Good resistance to coolant, water, and weak acids

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry