Silicon Profiles

Silicon Profiles Specification

- Ash %

- 1%

- Color

- Red, White, Transparent, and other custom colors

- Resistance level

- High resistance to temperature, moisture, acids, alkalis, weathering, and UV

- Thickness

- 2 mm to 40 mm

- Volatile Matter (%)

- 1%

- Rubber Type

- Silicone Rubber

- Width

- 10 mm to 100 mm (customizable)

- Product Type

- Silicon Profiles

- Natural Rubber

- No, made from synthetic silicone rubber

- Part Type

- Extruded profile

- Components

- Silicone polymer, additives

- Compression Ratio

- Up to 20%

- Weight

- Depends on dimensions

- Density

- 1.25 Gram per cubic centimeter(g/cm3)

- Usage & Applications

- Sealing, insulating, weatherproofing, vibration absorption, glazing, construction, electrical, mechanical, and general industrial applications

- Tolerance

- 0.2 mm

- Water Absorption

- <0.5%

- Diameter

- 4 mm to 50 mm (for round profiles)

- Surface Finish

- Smooth/Matte

- Length

- Up to 50 meters (customizable)

- Size

- Standard and custom sizes available

Silicon Profiles Trade Information

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Domestic Market

- All India

About Silicon Profiles

Being the pioneer manufacturers, exporters and supplier, engrossed in providing of superior quality range of Silicon Profiles. The provided profiles are manufactured at our ultra modern manufacturing unit by using the best quality silicon and hi-tech technology under the supervision of highly experienced professionals. These profiles are used in vehicles and in the construction of various buildings. Furthermore, these Silicon Profiles are available in various specifications at industry leading price.

Features:

-

High durability

-

Easy to install

-

Abrasion resistance

-

Perfect finish

Versatile Solutions for Multiple Industries

These silicon extruded profiles are specifically engineered to provide high performance across demanding environments. Thanks to their excellent chemical resistance and mechanical properties, they are suited for use in construction, electrical insulation, glazing, vibration absorption, and a variety of industrial sealing and weatherproofing applications.

Customizable for Optimal Project Fit

Available in widths from 10 mm to 100 mm and thicknesses from 2 mm to 40 mm, these profiles can be produced in profiles up to 50 meters long. Clients can request custom shapes, dimensions, colors, and hardness levels to match their specific functional and aesthetic requirements. They are supplied in coils, rolls, or cut lengths.

High Durability and Regulatory Compliance

Silicon profiles exhibit low water absorption (<0.5%), an ash and volatile matter content of 1%, and resist high temperature, acids, alkalis, and environmental factors. These products are REACH compliant, ensuring they adhere to strict environmental and safety standards. Food grade options can be provided to meet industry regulations.

FAQs of Silicon Profiles:

Q: How are silicon profiles with high elongation at break beneficial for industrial applications?

A: The high elongation at break (250% to 600%) ensures these silicon profiles can absorb significant stress and deformation without breaking, making them ideal for sealing, vibration absorption, and components exposed to movement or pressure fluctuations.Q: What customization options are available for these silicon profiles?

A: Customers can tailor the shape (e.g., rectangular, round, custom), color (red, white, transparent, or custom), hardness, dimensions (width, thickness, length), and packaging (coils, rolls, cut lengths) to suit unique project requirements.Q: When should food-grade silicon profiles be specified?

A: Food-grade variants should be requested when the profiles will come into direct or indirect contact with food or beverages, as they comply with safety standards for food processing and packaging industries.Q: Where are these silicon profiles typically used?

A: They are widely utilized in sealing, insulating, weatherproofing, glazing, construction, electrical, mechanical, and a variety of general industrial applications owing to their versatile properties and durability.Q: What is the process for ordering custom silicon profiles?

A: Clients provide detailed specifications including desired dimensions, shape, color, hardness, and application needs. The manufacturer then extrudes the profiles to match these requirements and supplies them in the chosen packaging format.Q: How does the excellent dielectric strength enhance electrical insulation applications?

A: With dielectric strength of 20 kV/mm and high electrical insulation, these silicon profiles effectively prevent unwanted electrical conduction, making them highly suitable for insulating cables, panels, and electrical enclosures.Q: What are the benefits of high ozone and chemical resistance in these profiles?

A: High resistance to ozone and chemicals ensures longevity and consistent performance, even in harsh environments. This minimizes maintenance costs and the risk of degradation from environmental exposure or corrosive substances.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Profiles Category

Thermoplastic Profiles

Width : Available from 5 mm to 100 mm

Resistance level : High chemical and corrosion resistance

Color : Black, White, Grey, Custom colors available

Product Type : Thermoplastic Profiles

Usage & Applications : Industrial sealing, edging, insulation, and protective trim

Weight : Depends on profile size, typically 100g 2kg/m

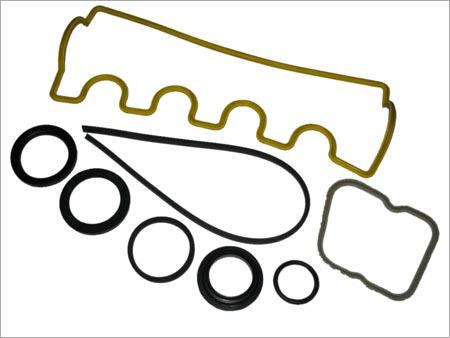

Endless Rubber Gaskets

Width : Up to 300 mm

Resistance level : High resistance to abrasion, oil, and chemicals

Color : Black

Product Type : Endless Rubber Gasket

Usage & Applications : Industrial sealing, Pipeline flanges, Hydraulic and pneumatic systems

Weight : Varies with size

Rubber Gaskets

Width : Customizable, standard range: 5 mm to 1200 mm

Resistance level : High resistance to oil, chemicals, weathering, ozone, and abrasion

Color : Black or as per requirement

Product Type : Rubber Gasket

Usage & Applications : Sealing, insulation and vibration absorption in pipelines, flanges, pumps, automotive, and industrial machinery

Weight : Varies with size and thickness

Pipe Clamps Rubber

Width : Customizable as per pipe size

Resistance level : Good resistance to coolant, water, and weak acids

Color : Black (Rubber); Silver (Clamp)

Product Type : Rubber Lined Pipe Clamp

Usage & Applications : Used for supporting and securing pipes in plumbing, HVAC, and industrial installations

Weight : Depends on clamp size

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry